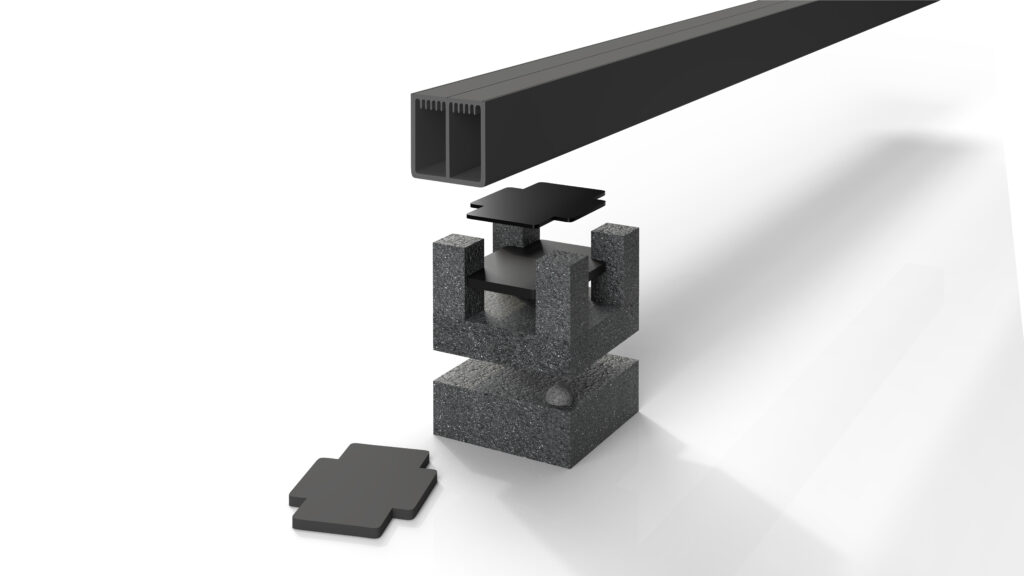

Cradle and Batten

Acoustic Flooring

Up to 30% faster to install compared to using traditional screed, with the potential to save weeks on construction timelines.

We design and manufacture a range of cradle and batten acoustic floor combinations and system depths suitable for both new build and redevelopment.

InstaGroup’s patented cradle and batten flooring exceeds Building Regulation and ADE requirements for sound and impact transference.

Our acoustic floors are engineered to work with and can improve the energy efficiency of underfloor heating. We can install underfloor heating at the same time as our acoustic flooring to speed up construction programmes.

We have IFC accreditation and can install Fire Batts as part of our package to give a ‘one-hour’ fire rating.

Why specify our systems

Our unique patented system has been specified for large-scale projects and landmark buildings across the UK. It’s proven to deliver outstanding acoustic performance for both residential and commercial projects.

- Quicker construction sequencing leading to cost savings

- Easy to adjust floor heights on-site, overcoming uneven surfaces

- We offer a complete design, supply and fit service

Our Cradle and Batten System

-

Manufactured with recycled and/or sustainable components

-

No screed means lower embodied carbon in the building

-

Lightweight solution minimises structural loading on the building

The downsides of screed

- Cement screeds have high levels of embodied carbon, increasing the environmental impact of construction

- Contractors waiting and screed drying times delays the construction sequence

- Uses huge amounts of water

- The heavier system requires a stiff slab

- Wet trades are messy on-site

The upsides of cradle and batten

- Less environmental impact than using screed

- Air is a great insulator of sound, and when it’s combined with insulation (rubber cradles) it delivers a superior acoustic performance compared to screed laid onto the slab

- Fast installation that provides a consistently level floor

- The dry system uses no water and there’s no delay waiting for curing/drying. When the last board goes down, the next trade goes in.

- When specified at the initial building design stage, the lower weight and less loading can reduce the amount of structural concrete and rebar required

- Offers greater constructability/customisation: different cradle heights and packers underneath the battens can achieve a level floor finish on an uneven slab

- 60-year guarantee

-

C40 cradle and batten acoustic flooringSouth Quay Plaza, London

-

C40 cradle and batten acoustic flooringBattersea Park, London

The quality of installation at Greenwich Peninsular (GPUR) was excellent. If, like with any trade, there was an issue, Insta attended to it straight away – again with no complaint, excuse or argument.”

Guto Jones, Project Director, Mace

Get in touch for more information on InstaGroup cradle and batten acoustic flooring